Chemical Manufacturing Management Software

In the present era, the chemical industry plays a crucial role in promoting the development of other economic sectors. However, during the management of the production processes, managers often have to face various challenges such as difficulty in managing product volumes, inventory management, and ensuring the safety of the production process. Therefore, chemical manufacturing management software is an optimal solution to manage the production processes conveniently and effectively.

Features of Chemical Manufacturing Management Software

- Production Process Management

- The software allows you to specify each stage in the production process. It facilitates coordination, scheduling of workforce, and allocation of time and materials for the most efficient production process.

- Define the operational objectives of each process, providing favorable conditions for closer, more specific monitoring and evaluation of activity results.

- Ensure each stage’s requirements in terms of labor, materials, machinery, equipment, etc., to ensure safety during the chemical production process.

- Raw Material Management

- The software helps managers determine each typical raw material attribute containing the quantity, weight, and status.

- Classify raw materials for quick recycling and use.

- Report on the usage status of each type of raw material to plan timely handling.

- Product Management

- Store data about manufactured products over a specific period: quantity, quality, prices, etc.

- Classify products based on their characteristics for easier distribution and transportation.

- Quantify inventory, defective products, and damaged or faulty items for timely handling, ensuring production progress.

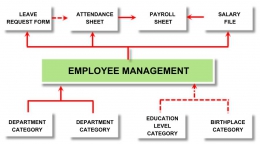

- Human Resources Management

- Supervise the workforce systematically and specifically: working hours, break times, workload, work productivity, etc.

- Monitor each employee’s activities. Store work records, contracts, and employee insurance systematically.

- Ensure employee operations through regular reports.

- Financial Issue Management

- Track the company’s financial situation regularly: cash, receivables and payables, revenue sources, expenses, etc.

- Determine an employee salary system suitable for work capacity and each employee’s dedication time.

- Store production contracts, invoices, etc.

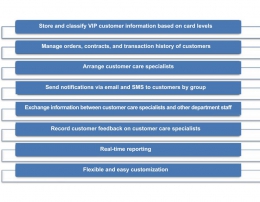

Utilities of Chemical Manufacturing Management Software

- Management Anytime, Anywhere

- Users can access the data system anytime, anywhere If they have an internet-connected device. It helps managers quickly detect emerging issues and address them promptly.

- Unified Data Management

- All data and information of the chemical manufacturing plant are stored in a single system, allowing managers to manage and retrieve data quickly and easily.

- Safety and Security

- With role-based permissions, managers can limit the access area and data operation rights for different users, ensuring synchronized management while securing essential information.

- Cost-Effective and Flexible

- With the help of a flexible customization feature, the software is not restrained by a specific template. You can build it according to the workflow and needs of each business or manufacturing plant.

Using chemical manufacturing management software, users can smoothly and effectively perform management tasks, ensuring that the manufacturing process is carried out systematically and efficiently. If you have any questions about the software’s functions and basic features of chemical manufacturing management software, please contact us for further consultation.