Garment Management Software

Introduction of Garment Management Software

In garment manufacturing plants, the production process of increasingly complex product orders and prolonged processing sequences have elevated the demand for robust information technology infrastructure. Information technology infrastructure in large factories encompassing activities from fiber drawing to weaving and garment production is critical. The FACEWORKS clothing manufacturing management software assists businesses in managing core functions such as production planning, incoming inventory management, warehouse stock storage, supplier interactions, providing services to customers, and order tracking.

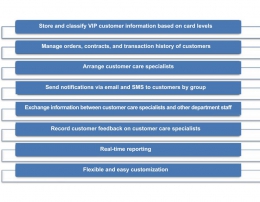

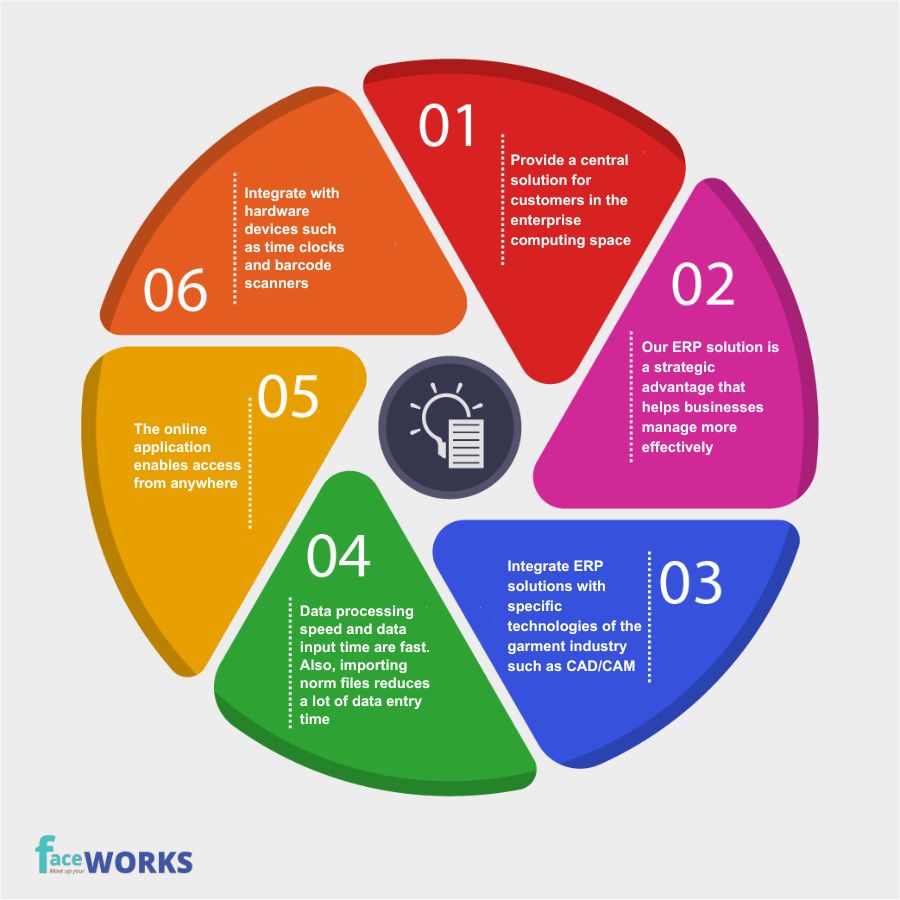

Utilities of the Software

Functions of the Garment Management Software:

- Uploading the standard file directly into the software:

- Support extraction of dyeing standards into Excel files.

- Directly import dyeing standards Excel files into the software.

- Directly import dyeing standards Excel files into the software.

- Order Management:

- Receive and process orders from customers.

- Calculate production capacity and decide whether to accept orders.

- Estimate the production cost of the product.

- View the transaction history of previous raw material orders.

- Check inventory of raw materials to make purchasing decisions.

- Manage the sales process.

- Manage profit/loss by contract and item code.

- Procurement Management:

- Receive purchases from departments.

- Create purchase orders for suppliers.

- Manage raw material inventory.

- Manage the supplier’s delivery process.

- Manage accounts payable.

- Production Order Management:

- Receive production requests from the sales department.

- Create production orders based on production requirements.

- Establish consumption standards.

- Calculate material consumption for each production order.

- Inventory and statistics of completed products at each production stage.

- Control production schedules.

- Quality Control and Production Progress Monitoring:

- Define specific quality control regulations for each item.

- Inspect each item and batch for analysis and multiple sample printing.

- Update and compare with standards for approval or rejection of materials.

- Print inspection certificates.

- Monitor supplier deliveries.

- Monitor the progress of production.

- Finished Product Inventory Audit:

- Manage all transaction data in the software.

- Track shipment batches with production and expiration dates.

- Generate warehouse reports.

- Generate entry reports for each item.

- Warehouse Inventory Audit:

- Record finished product invoices in the warehouse.

- Record sales revenue in the warehouse.

- Record information on the transportation of goods in the warehouse.

- Generate warehouse reports and other requested reports like revenue for products in the warehouse, revenue by product, revenue by region, etc.

- Reporting System:

- Specific period revenue report.

- Specific period cost report.

- Inventory report.

- Actual production report.

- Other customers requested reports.

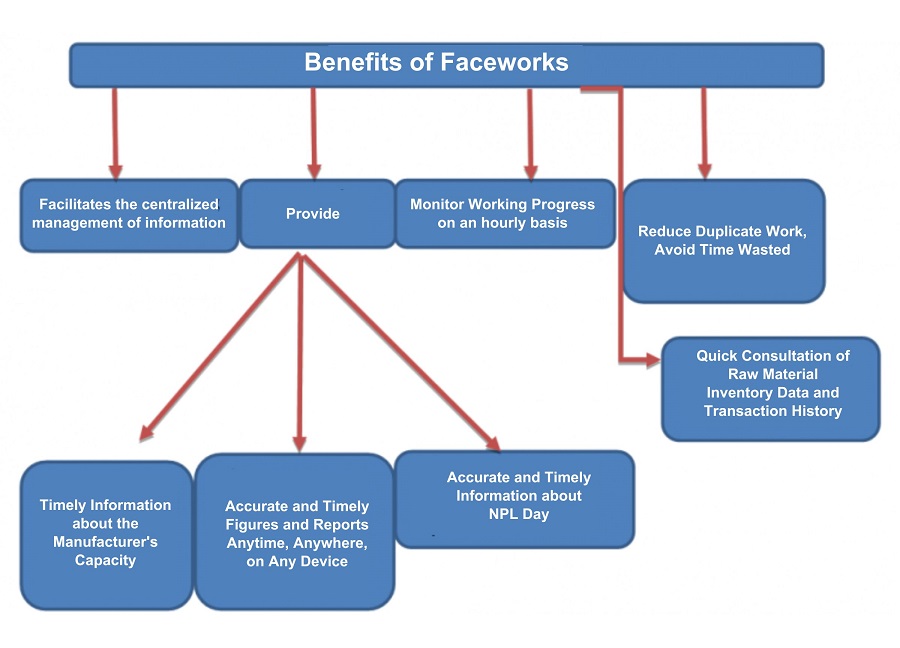

Benefits of Garment Management Software:

Faceworks by TIT is an open-source management software designed for the apparel industry. This system allows businesses to easily configure the software according to their specific operational processes without altering existing workflows. The apparel management software empowers leaders to oversee operations from the design phase to production, providing insights into production capacity, raw material consumption, and labor. Our software ensures all of your schedules, quality, and order will meet your requirements.