Manufacturing Outsourcing Mechanical Management Software

The software for managing the mechanical processing industry developed by TIT is based on practical experience and research into management models at mechanical manufacturing businesses. This is one of the optimal solutions to address the following challenges: Small-scale, scattered production, limited capacity, production of simple products, and lack of competitiveness in the market.

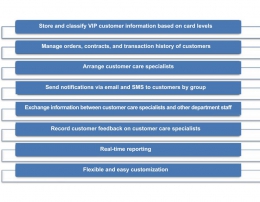

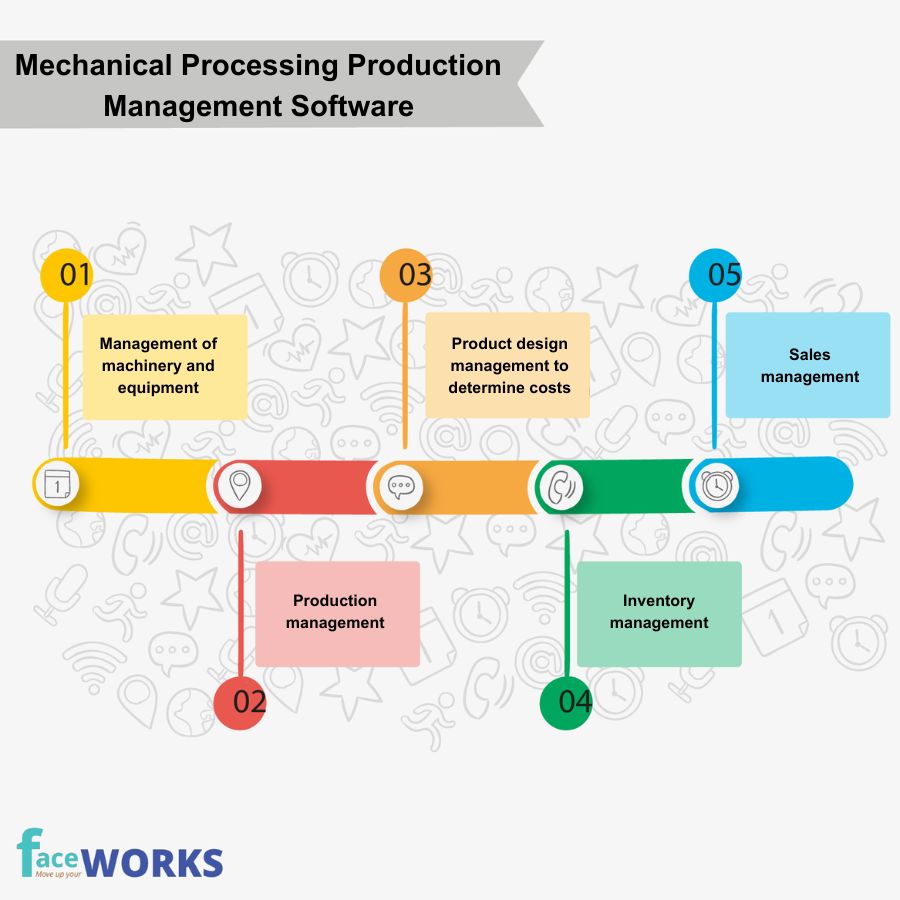

Functions of Faceworks Mechanical Processing Production Management Software

- Extract and Upload the Norm File to the Software

- Support businesses in extracting quantities into an Excel file

- Directly import the Excel file of the bill of quantities into the software

- Automatically provide quantities for the production process

- Product design management and cost calculation support

- Store information about the product design: shape, product’s function, expected raw materials needed, etc.

- Store soft copies of the design images.

- Assist managers in assigning production according to product details and managing based on product quantities.

- Support pricing calculations based on the quantity and quality of materials needed for production.

- Assist in updating expected raw materials and labor to provide a cost for producing the finished product.

- Production management

- Receive orders from the sales department. The production program is connected to sales. Collecting purchase orders is the basis for creating internal production orders.

- The production plan is built based on the quantity of orders, the quantity of items in the order, inventory levels, and the structure details of the product and labor force of the business. Use mechanical processing management software for syncing all data.

- Support the generation of production reports based on the stored data in the software.

- Support the creation of production orders, issue production orders, and track the details of each production order for each component that makes up the product.

- Monitor the production progress based on production orders, and the statistics department inputs data into the system compared to the production plan.

- Support the input of material forecasts based on the number of orders, the number of items per order, and product design in the software database.

- Warehouse Management

- Notify the inventory levels of each item. Alert the expiration dates of those items. The most useful function is to help businesses prioritize items that are expiring soon, have a large quantity in stock, or build a plan to purchase lacking materials.

- Inventory in and out by managing the number of goods in stock and issuing goods using barcodes.

- Detailed management of raw materials based on specifications and multiple units of measurement.

- Sales Management

- Automatically send SMS or emails to introduce new products and congratulate customers on birthdays and New Year.

- Automate sales and marketing programs on holidays and festivals.

- Analyze trends and customer needs based on personal information and past transactions.

- Equipment Management

- Provide notifications about scheduled inspections and inform about the probability of checking the machinery and equipment. This method helps prevent unexpected broken-down machines in the system, avoiding disruptions in the production process. The risk of budget deficits due to repairs and delays in orders is eliminated.

- Give additional notifications for timely replacement or supplementation of machinery and equipment based on inspection and synchronized production information on the software.

- Reporting System

- Revenue reports.

- Expense reports.

- Inventory reports.

- Other customers requested reports.

Benefits of FACEWORKS Software

- Manage Anytime, Anywhere

- Users can access the data system anytime, anywhere, as long as they have an internet-connected device, enabling managers to quickly detect emerging issues for addressing promptly.

- Unified Data Management

- All data and information from the water production and distribution plant are stored in a single system, allowing managers to quickly and easily manage and retrieve information.

- Safe, Secure

- With the role-based access control feature, managers can limit the search area and data manipulation rights for different users. This helps synchronize management while maintaining the security of important information.

- Flexibility

- With the flexible customization feature, not following any specific template, the software is built according to the workflow and needs of each business. Therefore, it is suitable for both customers’ characteristics and their water usage needs.

Nowadays, the mechanical processing industry in Vietnam is dealing with many difficulties due to the diversity of products from abroad, limited management methods, and human resources in the mechanical processing industry. To increase productivity, maximize profits, survive, and develop, mechanical processing businesses should update new technologies and apply new software.

If your company wants to try out the software, please register here.