Production Management Software

TIT introduces the best production management software for manufacturing enterprises. Each manufacturing business has different management methods and processes, requiring flexible software that fully and accurately meets those management processes and methods. Understanding this need, TIT Service and Technology Joint Stock Company has developed the “Faceworks” production management software. As highly customizable software, it is suitable for the requirements of various types of businesses (wood industry, electronics manufacturing, textile industry, packaging, etc.). The software helps manufacturing enterprises manage detailed information about raw materials, inventory, and product orders without changing management processes.

Functions of Production Management Software

- Data Management

- Manage material categories, semi-finished products, and finished products.

- Manage conversion factors for each type of material.

- Manage material prices based on periods and material codes.

- Manage labor prices and labor factors over time.

- Manage both material and labor standards.

- Oversee the catalog of production processes.

- Manage production capacity for each department.

- Handle material planning.

- Allocate data efficiently.

- Manage production requirements and orders.

- Monitor production plans.

- Control production batches.

- Supervise delivery schedules.

- Handle purchase requisitions.

- Manage error catalogs.

- Control quality assurance processes.

- Handle inventory operations, including input, output, and storag

- Automated System Calculations and Alerts

- Automatically calculate material plans.

- Support direct file import for standard norms and materials into the software.

- Automatically balance material plans after allocation.

- Automatically allocate material for production requests.

- Automatically create production orders.

- Automatically calculate the cost for products at each stage.

- Automatic system alerts for minimum inventory levels.

- Automatic creation of purchase requisitions.

- Alert system for material usage.

- Theoretical inventory balance system.

- Automatically trace the origin of materials.

- Automatically update production plan progress evaluation.

- Customize software system for detailed management of each characteristic of every stage.

- Chart and Reporting System

- Visual standard norm chart.

- Have a statistical production capacity chart for each stage.

- Input material production reports for each stage.

- Progress report system for the fulfillment of production requests for each stage.

- Quality management reporting system.

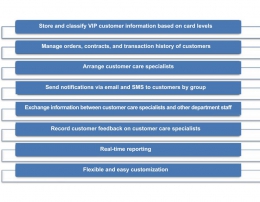

- Benefits of Production Management Software

- Facilitate managers in devising solutions to boost revenue and reduce production costs for the business, offering timely and effective measures in production and business operations.

- Provide continuous, up-to-date, and accurate insights into the business’s production and operational dynamics.

- Centralized information management makes searching and categorizing information easy, aiding in identifying the most suitable processes for the business.

- Streamline communication and support task handling among employees and departments.

- Allow employees in various departments to provide regular updates on progress and task completion without face-to-face meetings.

- Assist in calculating completed and pending workloads, enabling employees to set specific and accurate plans for task completion.

- Feature a real-time reporting system to keep stakeholders informed and up-to-date.

- Easily customizable when there are changes in workflow processes.

- Utilities of the Software

TIT’s Production Management Software is a comprehensive solution designed to meet the full spectrum of production management needs for businesses. The system is built on a closed-loop process, starting from order creation and production requirements to production planning, determining and calculating the supply capacity of materials in stock, establishing material standards for each production stage, costing, depreciating material rates, to monitoring and supervising the production progress for each order and production stage.

If your business is interested in using the software, please contact us for a detailed consultation or register here.