Steel Industry Management Software

Every business, each department within a business, and especially in the steel industry, has unique characteristics and management methods. It necessitates flexible and comprehensive management software that can adapt to specific working processes and management methods. Recognizing the diverse needs of businesses in the steel industry, TIT Corporation has introduced Faceworks, a management software tailored for the steel industry. The most important advantage of this software is its ability to assist leaders at all levels in the management process, alleviate workload pressures, organize tasks efficiently, expedite workflow, and maximize profits.

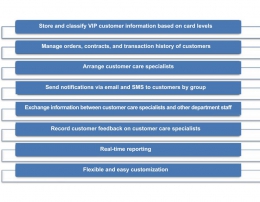

Prominent Features of the Faceworks Steel Industry Management Software

- Warehouse Management

- Inventory Management. Support the printing of invoices for goods receipt and issuance.

- Managing raw materials in the warehouse in various units of measurement (cm, m, km, g, kg, ton, bag, box, etc.)

- Manage by Standards. The software will help store data for calculating the quantity of materials before they are put into production. The software can assist in building standards even when the units of the product, units of various finished products, and raw materials are different. Here is an example: producing a U-shaped steel bar – raw material 1: 10 grams of scrap iron, raw material 2: 10 grams of iron scrap, and raw material 3: 10 liters of oxygen.

- Inventory management: indicates the amount of raw materials in stock. Thanks to reporting, statistics, and alert systems, businesses can understand the number of raw materials available. It helps avoid risks of damage, erosion when too much raw material is stagnant, raw materials shortages for production, and shortages of products released to the market when raw materials or finished products run out.

- Managing the location in the warehouse: the software supports managers in managing storage areas. Specifically, It can supervise storage areas by each row, shelf, and shelf level.

- Management of Processing Orders and Calculating Losses to each Cutting Line.

- Currently, the steel production system has been automated. Therefore, issuing processing commands helps ensure continuous and accurate work, minimizing human effort. On the other hand, synchronized production equipment and simultaneous command execution help align steps in the process, eliminating delays due to subjective factors of human intervention. Steel production involves substantial consumption of costly and challenging-to-obtain raw materials and fuel, and it is not limitless. Efficiency in material and fuel usage, known as yield, is one of the ways to conserve resources and budget for the company.

- Detailed Product Costing for each Stage of Production

- After each stage, the software will update the amount of money spent. Calculating based on the production stages minimizes the risk of overlooking certain expenses. Generalized calculations can lead businesses to set selling prices equal to or lower than production costs.

Benefits of Faceworks Steel Industry Management Software:

- Have no limitations on the business scale or type of operation.

- Reasonable deployment costs thanks to flexible customization and web-based platform.

- Support managers in easily accessing reliable information to make informed decisions based on comprehensive data.

- Users can access the system’s data anytime, anywhere, as long as there is an internet-connected device, enabling managers to detect emerging issues quickly. Address them promptly.

- -All data and information from the production workshop are stored in a single system, allowing managers to manage and retrieve information quickly and easily.

- Despite all employees and managers working on the same system, the permission function allows managers to limit the search area and data operation rights for other users. It helps synchronize management while securing critical information.

- With flexible customization, not following any specific template, the software is built according to the workflow and needs of each business, making it suitable for various production workshop models and easy to change to meet the business requirements.

- Enhance the safety and accuracy of information through access permissions to the software system.

Steel production plays a crucial role in heavy industry; however, it requires significant raw materials, fuel, and specialized labor. Moreover, the materials and fuel used in steel production are not reusable. It is essential to have proper management methods to save resources and still achieve maximum profit. The Faceworks Steel Industry Management Software is undoubtedly one of the perfect choices for the leadership levels of businesses in this field.