Toughened Glass Manufacturing Management Software

Manufacturing toughened glass through outsourcing is an industry that demands precision and professionalism. Businesses engaged in this type of glass production often have to deal with numerous challenges in managing the operations of their manufacturing plants. We understand the difficulties and intricacies involved in this industry. To address these challenges, we offer a highly effective solution for businesses. It is Faceworks Manufacturing Management Software, which we have specifically designed for toughened glass production. Our Manufacturing Management Software for toughened glass is a standout product within the comprehensive Faceworks software system. Leveraging the latest and most advanced technologies available today, the Faceworks Manufacturing Management Software allows users to access it anytime, anywhere, without installations. It provides quick access through web browsers, offering convenience and ease of use across various devices.

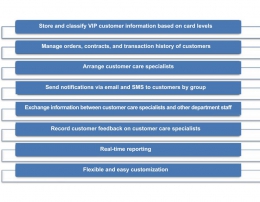

We now introduce some notable features of Faceworks Toughened Glass Manufacturing Management Software.

- Rigorous Order Control

- Every day, toughened glass manufacturing businesses receive massive orders, each with diverse specifications such as size, drill hole positions, and lens grinding requirements. Managing orders through paperwork can make it challenging for businesses to maintain control, leading to oversight of crucial orders and delays in the toughened glass production and delivery procedure. Additionally, managing verbally or through paperwork makes it difficult for each worker and manager to grasp the progress of each order. It can impact the company’s reputation and responsibility. Using Faceworks’ manufacturing management software, which features extensive information storage capabilities with no limit on the number of updated orders in the system, will help businesses manage orders more closely and monitor the completion progress of each order.

- Workforce Responsibility Management

- Glass, being a fragile material, requires meticulous care during processing, making it prone to errors and breakage. Identifying the responsible worker for any breakages becomes hard when multiple workers are involved. Lack of accountability for breakages can lead to financial losses for the business. The software’s feature of storing detailed information on each order and the individual responsible for each processing stage facilitates easy identification of the person responsible for breakages, ensuring accurate accountability.

- Strict Material Management

- Some orders may require smaller-sized glasses, resulting in leftover glass after processing. Instead of discarding these remnants, they can be reused for new orders requiring smaller sizes, effectively saving costs. However, manually managing and tracking these remnants can be challenging. Storing barcode information for each remnant using the software’s system helps businesses efficiently manage this inventory.

- Productivity-Based Salary Calculation

- As order volumes increase, inefficiencies in worker performance can affect business operations. Calculating salaries based on productivity while not having accurate information on who performed grinding, cutting, etc., can lead to stagnation in worker productivity. Faceworks’ software system stores daily work information for each worker, accurately calculating productivity and motivating employees to enhance work efficiency.

- Production Process Procedures

- Toughened glass manufacturing involves multiple stages encompassing cutting, grinding, drilling, and toughening the glass. If you do not use a streamlined production process, it will become hard to track the progress of each product and the stage it has reached. Synchronizing product information with all departments involved in the production process is crucial to avoid miscommunication and ensure that every department is well-informed about each order, material, and work progress.

Please contact us for a detailed consultation if your business needs toughened glass manufacturing management software.